Nord-Lock Group is a global leader in innovative solutions designed to secure bolted connections. With technologies including Nord-Lock wedge-locking washers, Superbolt mechanical tensioners, Boltight hydraulic bolt tensioning systems, and Expander pivot pin systems, we prevent bolt loosening and ensure structural integrity. Serving critical industries such as energy, transportation, construction, mining, and defense, we provide engineering support, technical training, and customized solution development.

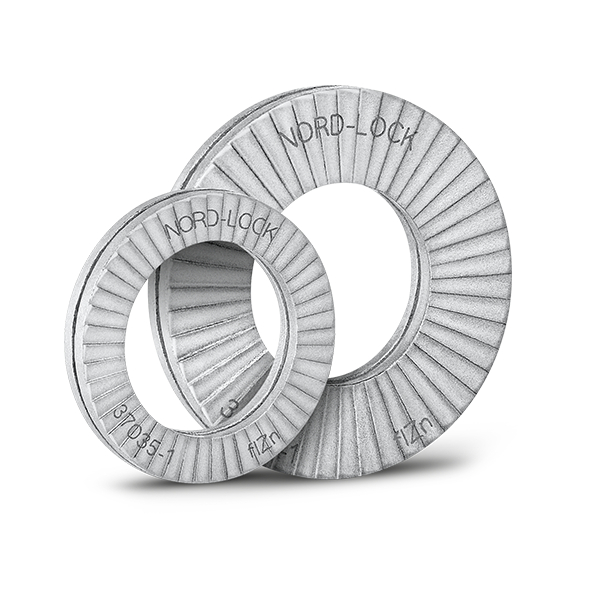

The Nord-Lock wedge-locking washer is a specialized two-piece system engineered to secure bolted joints by preventing spontaneous loosening. Each washer pair features cams on the inner surfaces and serrations on the outer faces; the cam angle is greater than the thread pitch, ensuring a reliable mechanical lock even under extreme vibration or dynamic loads.

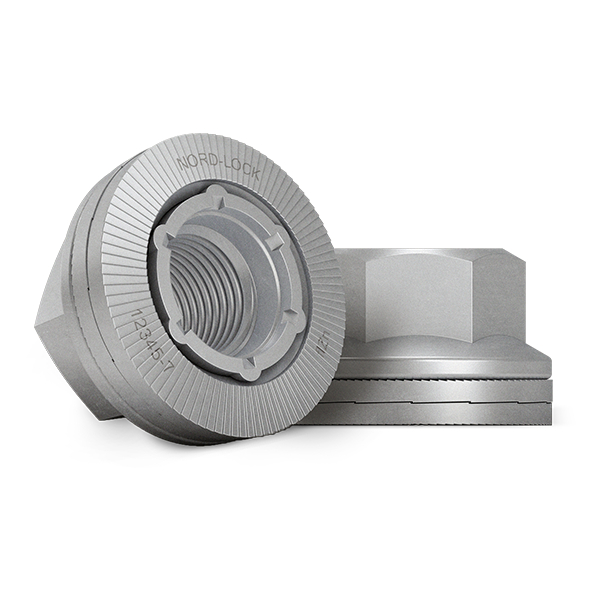

NORD-LOCK® Wheel Nuts are specially engineered safety nuts designed to prevent the loosening of wheel bolts on heavy-duty vehicles such as trucks, buses, and construction machinery. Each nut incorporates Nord-Lock’s proven wedge-locking technology, which ensures a secure connection by resisting loosening caused by vibrations, dynamic loads, or thermal expansion. These nuts are easy to install using standard tools and are reusable without loss of performance.

NORD-LOCK® Combi Nuts are innovative locknuts that combine a high-quality nut with integrated Nord-Lock wedge-locking washers, forming a one-piece, pre-assembled locking solution for bolted joints exposed to vibration and dynamic loads. This compact design simplifies installation, prevents loss of individual parts, and ensures consistent locking performance. The wedge-locking mechanism inside the nut provides a secure mechanical lock by using cam surfaces that counteract any loosening movement.

Utilizing a unique multifunctional design, Nord-Lock X-series washers combine Nord-Lock wedge-locking technology with compensation against settlements. The wedge effect prevents bolt loosening caused by vibration and dynamic loads, while the washer also reduces slackening and compensates against loss of preload, thanks to its conical shape.

Nord-Lock Steel Construction (SC) washers are wedge-locking washers specially designed for use on steel construction applications in accordance with the European standard EN 14399-3 /EN 14399-4 /EN 14399-8. The system consists of a pair of washers that use Nord-Lock wedge-locking technology. Each washer has cam faces on one side and serrations on the other. They also have chamfers on the inner diameter, which ensures optimal fit with HV bolts. Since the chamfer is present on both sides of each pair, it also eliminates the risk of incorrect installation.

Superbolt Multi-Jackbolt Tensioners provide a safe, reliable, and easy-to-use bolting solution by replacing traditional hex nuts or bolts. They use multiple jackbolts to apply high preload with simple hand tools, reducing the need for large torque equipment.

Boltight Hydraulic Bolt Tensioners deliver accurate and simultaneous bolt tightening using high-pressure hydraulics. Designed for critical applications, they ensure uniform preload, minimize bolt fatigue, and speed up installation. Widely used in wind turbines, offshore, power generation, and heavy industry.

The Expander System is a permanent solution to eliminate lug wear in pivot applications. It uses an expanding axle design that locks into the worn lug, providing a tight fit without welding or line boring. Proven in construction, mining, forestry, and heavy equipment industries.